FEATURES 事業間一貫体制の強み

- 世界中にアンテナをめぐらして、優良な電子部品を自社調達

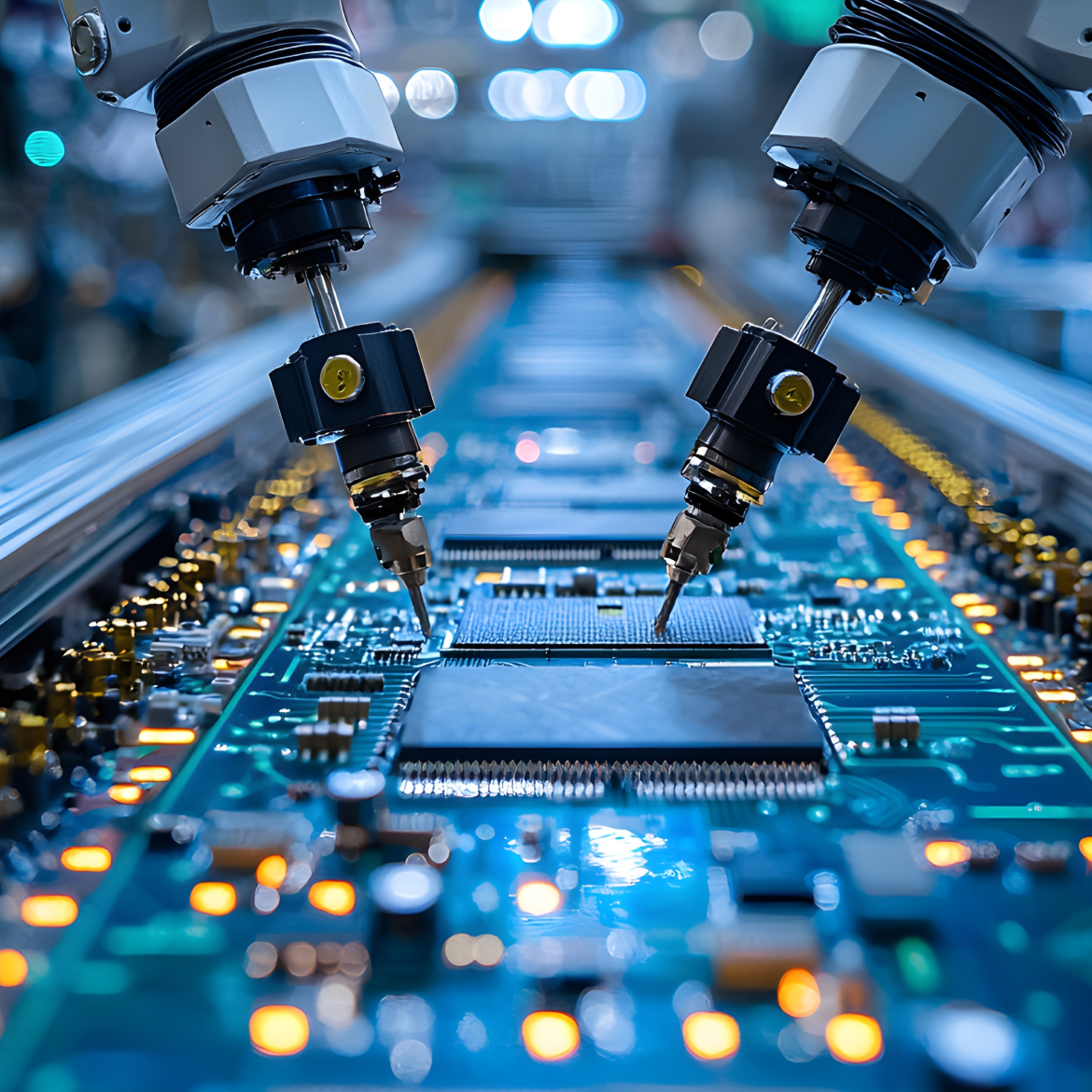

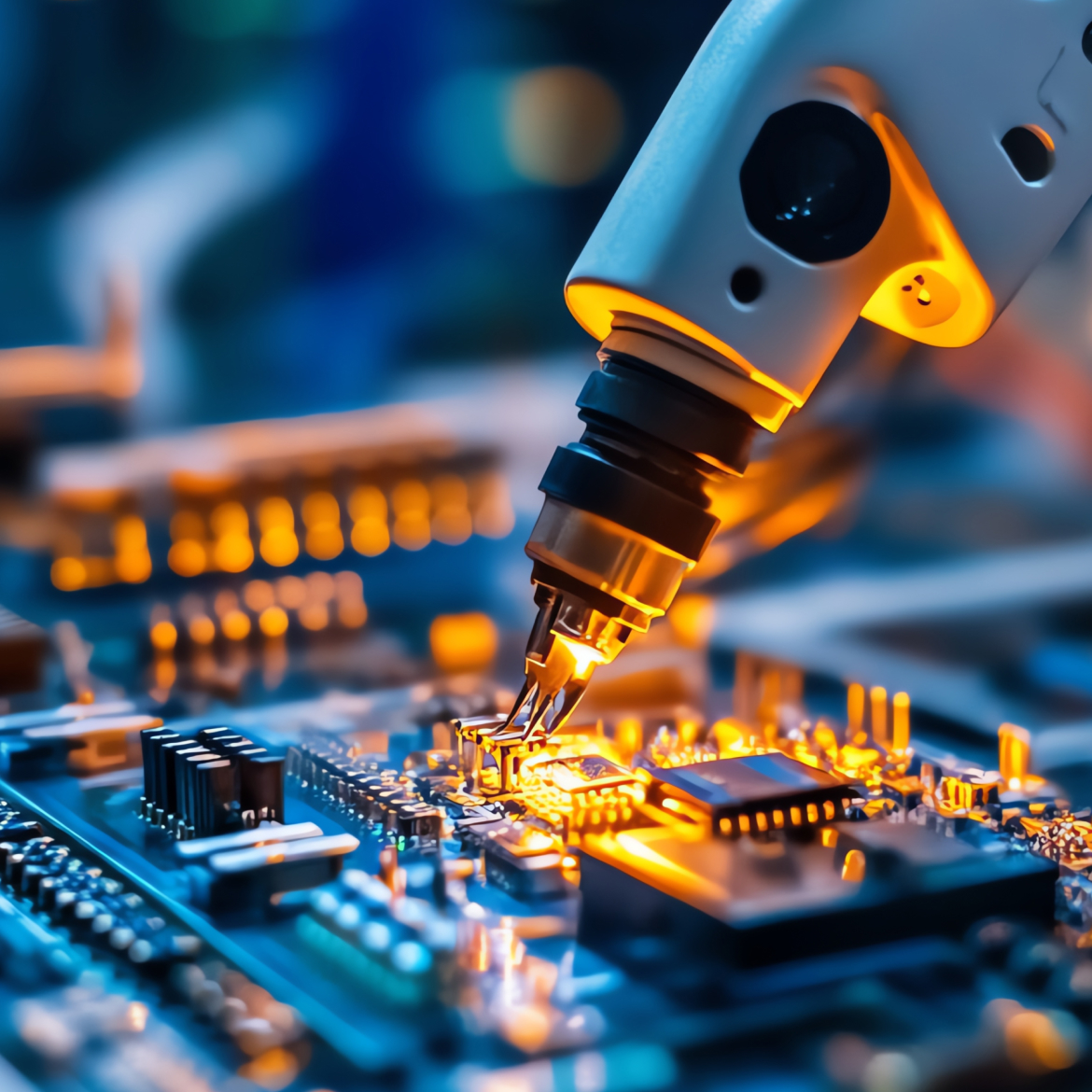

- デバイスの小型化・高密度化や環境に配慮した最新設備の導入

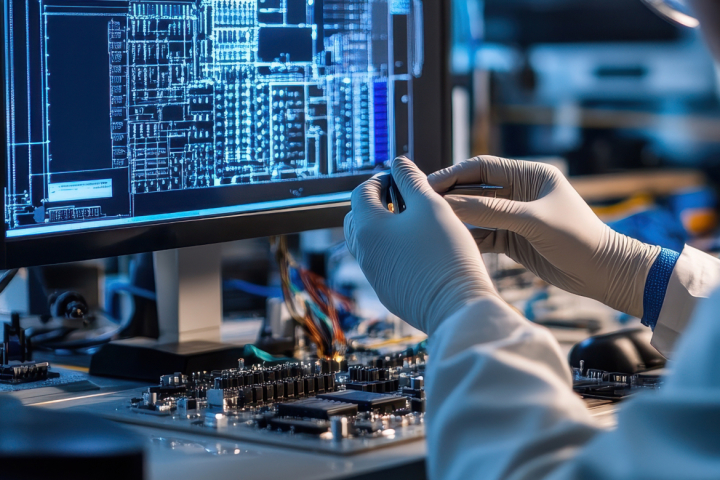

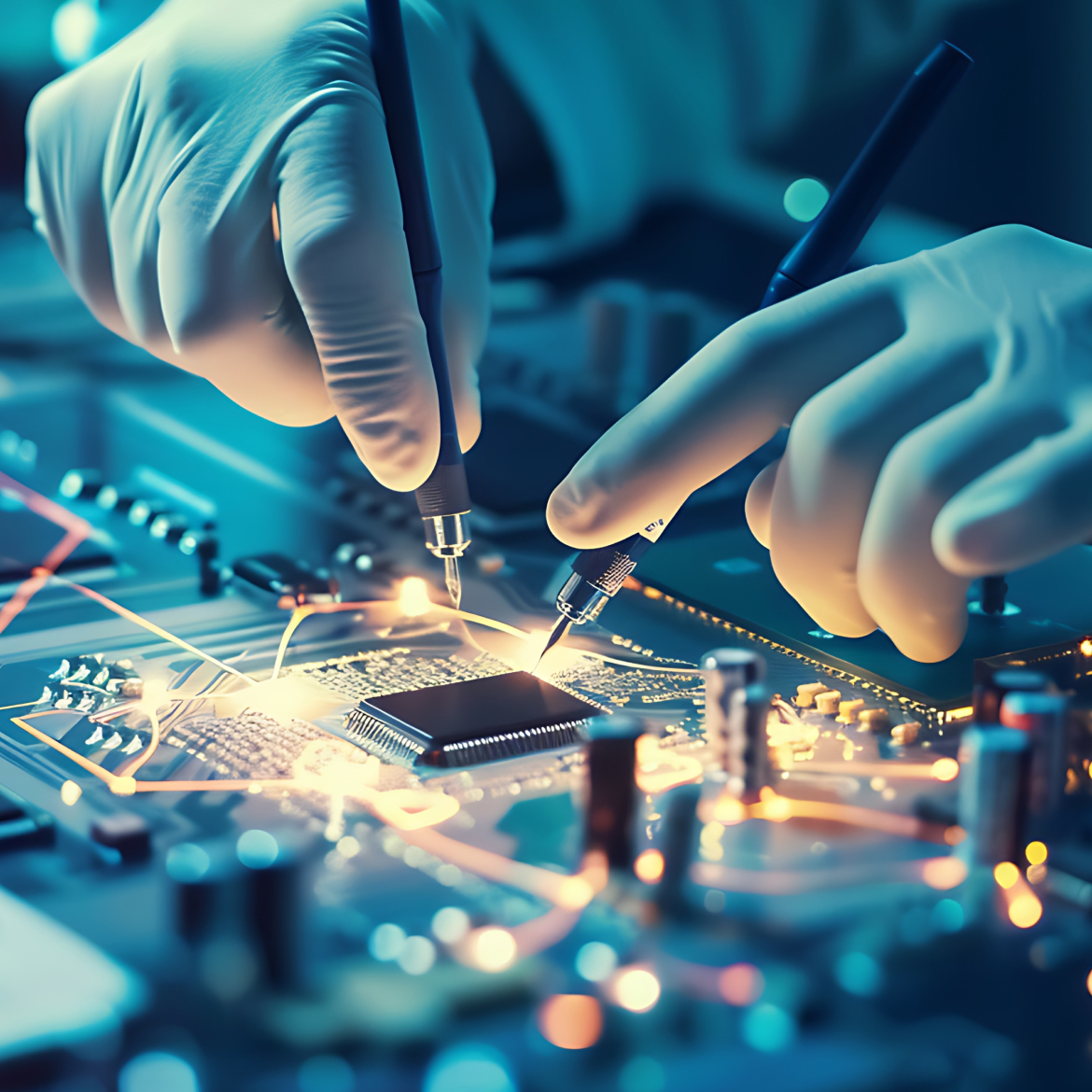

- 設計開発室と電子事業部が連携し、スムーズな製品化を実現

- 画像検査に注力した品質保証、比類のないAOIの設置数と集中管理

- 試作段階から量産までを見据えた、スピーディーな工程作成

- IATF16949・ISO9001を土台にDRBFMを踏襲した設計・評価プロセス

- 専門知識と豊富な経験、高い技術を誇るスタッフが在籍

- 生産設備・治具類は、自社製もしくはグループ会社製を採用